Energy savings with innovative paint solutions

In the painting process, curing and ventilation are often an overlooked area where huge energy savings can be made. With the energy situation expected to become more challenging in the near future, Teknos has been looking at how it can help its customers to reduce their energy consumption.

For over 20 years, in line with the company’s sustainability strategy, Teknos has been focusing on creating solutions for customers to reduce their energy consumption and increase efficiency. As curing is one of the most energy intensive parts of the painting process, Teknos has developed a range of energy-efficient, fast-curing products that continue to offer long-term proven performance.

How to save energy in the painting process

The ways to save energy in the painting process obviously vary depending on what kind of painting line and what kind of coating solutions are being used: the substrate, the paint chemistry, as well as the painting process all have an effect. Over the years Teknos has introduced a range of energy-efficient coatings, focused on the following curing properties:

Ambient fast curing, moisture curing – removes the need for oven curing

Low-temperature-curing powder coatings – reducing high temperature curing

Using infrared to cure low-temperature powder coatings

Using LED for curing – less energy usage than with mercury or gallium lamps

Lower temperature curing hardeners.

There are huge numbers of different coating methods and chemistries, so the curing methods are numerous, but many of them are quite energy intensive.

Save more than 60% energy when powder coating

High energy costs, low efficiency and an uncertain supply situation: there are a number of disadvantages and risks relating to gas-powered drying facilities. A pioneering alternative is IRT booster drying with a special Teknos powder paint.

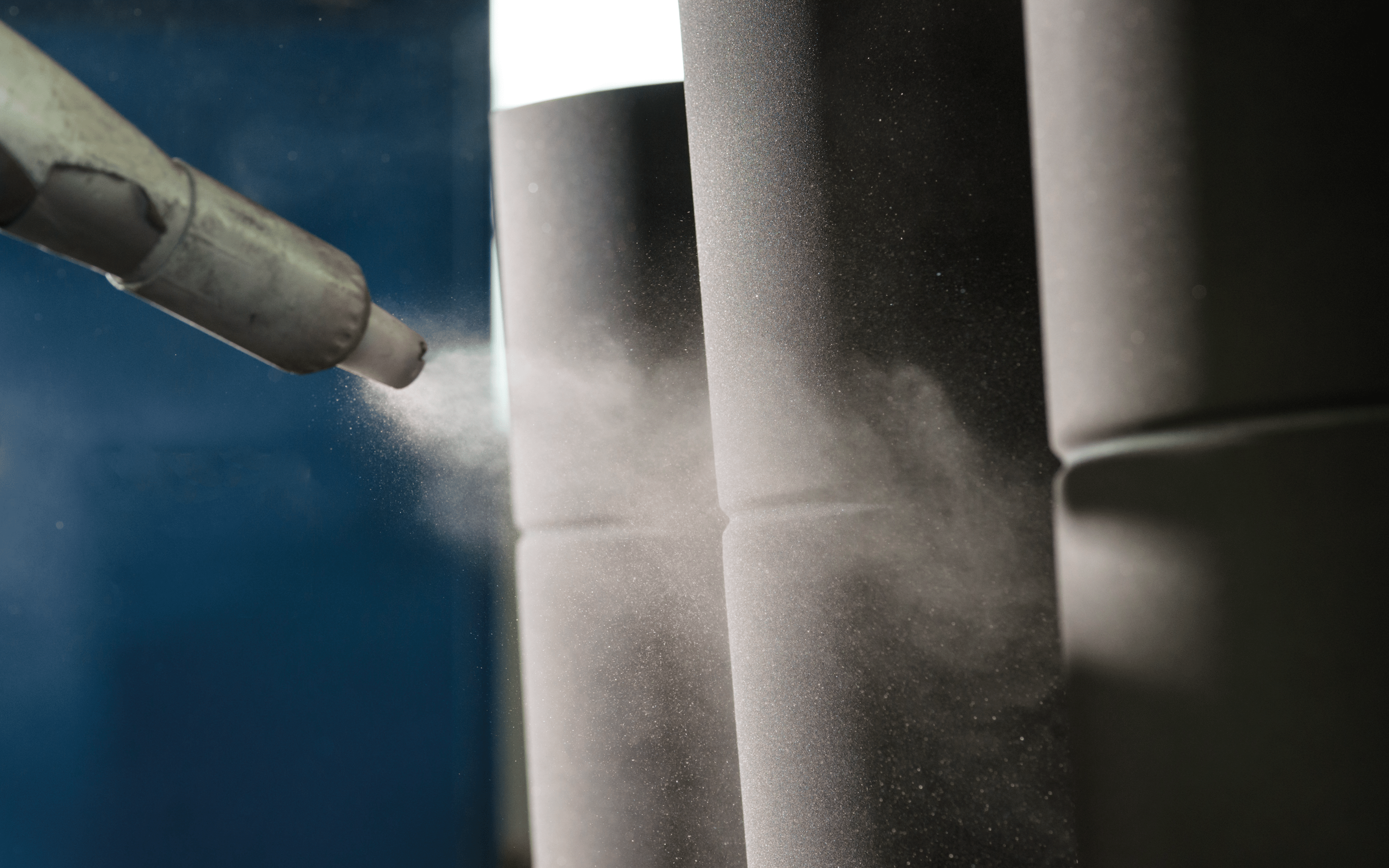

Powder coating processes using gas-powered convection ovens have a number of disadvantages: high energy requirements, low efficiency, long lead and follow-up times, and a high dependency on gas as an energy source. Teknos has developed an alternative for powder coating in collaboration with Hedson Technologies, the Swedish manufacturer of IRT infrared drying systems: an energy-efficient process with a special powder coating for low burn-in temperatures and booster drying with electric infrared emitters.

The IRT emitters are only activated when components pass the sensor barrier

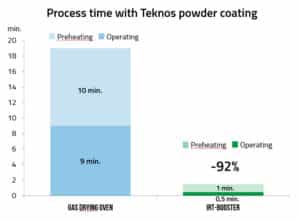

The powder coating of steel profiles, for example, showcases the advantages of the solution. Conventional processes in gas-powered drying facilities require a dwell time of approximately 9-10 minutes for heating and gelling, plus an additional 10 minutes for burning in. The oven operates continuously, even when the production line stops.

The IRT booster operates using a different process: here, electrically-operated quartz glass lamps act directly on the component. Separate gold-coated reflectors ensure that 98% of the emitted energy is actually utilised.

The IRT emitters are only activated when components pass the sensor barrier, and only in the defined zones required for the relevant component length.

Maximum efficiency with special Teknos powder

Teknos offers a special Infralit powder for this process. The powder paint was developed for low burn-in temperatures and accelerates infrared drying, thereby fully exploiting the potential of IRT technology.

Teknos powder increased the energy efficiency of the process by up to 50%. “During testing, it emerged that the process times of conventional low-temperature powders available on the market were three minutes or more,” explains Jörg Andres, Regional Sales Manager for Industrial Curing at Hedson Technologies. “With the Teknos powder, however, the paint on the same work piece had fully hardened in 90 seconds. As a consequence, Teknos powder increased the energy efficiency of the process by up to 50 per cent. The gelling and stopping zone was also significantly shorter, which means lower investment costs.”

Teknos offers a special Infralit powder developed with low burn-in temperatures which accelerates infrared drying

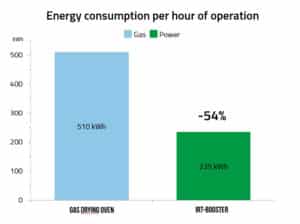

The savings potential is phenomenal. Instead of 510 kWh of gas required for conventional convector drying, the Teknos powder coating with IRT booster mentioned in the above example only requires 235 kW/h of electrical energy, which is 54% less. In terms of actual operating times, the reduction can be as much as 64%, because instead of preheating and operating continuously like a drying oven, the IRT emitters switch to standby during shift and colour changes as well as during cleaning and break times.

Impressive advantages

The booster process is more sustainable, economical and flexible. In addition to a significant reduction in CO2, it saves around 50% of the energy costs for the application example, which amounts to around €285,000 per year. In spite of the higher costs for the special powder paint, the investment amortises in only one or two years, or even faster if the company uses a photovoltaic system to generate its own electricity.

An additional advantage is that the process is faster and more flexible. Instead of spending around 20 minutes in the convector oven, the heating, gelling and burn-in process only takes about 90 seconds, which is more than 90% quicker.

Furthermore, set-up times no longer result in a loss of energy, which makes it easier to process smaller batch sizes and increase shift flexibility. The electric infrared drying of components with different sizes and masses is also more flexible because the emitter output can be adapted to each specific product using smart control technology.

Holistic optimisation of the powder coating process

The IRT system has a modular structure, can be adapted to specific customer requirements, and can also be easily retrofitted to existing facilities. Teknos and Hedson Technologies can provide joint support for process analysis and planning.

The optimisation of coating processes is being driven to an increasing extent by the drastic increase in energy costs and the uncertainty of energy supplies. Only considering individual factors such as the cost of the paint is simply inadequate. Instead, a holistic approach is required that also puts the drying technology to the test. IRT boosters combined with Teknos’s special Infralit powder coatings are a real game-changer here.

Energy saving with Teknodur Combi 3560

An excellent example of an energy-efficient coating is the moisture-accelerated curing Teknodur Combi 3560 product series. The 3560 series is a range of two-component, polyaspartic-based high-solid polyurethane coatings that enable fast curing and high throughput, whilst offering low VOC emissions and high durability.

How does it work?

Teknodur Combi 3560 products cure and crosslink quickly at ambient temperature. Instead of utilising energy and time-intensive oven curing, the 3560 products can be cured efficiently using air flow and moisture in a controlled environment. Heating an industrial oven might require a power supply of 50-100kW, whereas moisture-accelerated curing can be done for less than 1kW. That means that by switching from oven to moisture curing with 3560, around 274,000 kWh of yearly energy savings can be made, together with increasing productivity.

Teknodur Combi 3560 paint film develops hardness approximately 5-10 times faster than standard industrial polyurethanes and up to six times faster than regular polyaspartic paint products. So, alongside minimising the energy consumption, Teknodur Combi 3560 products can also increase productivity.

The painting and curing process is often a bottleneck in production lines. Teknos can also help to improve painting capacity and decrease energy consumption.

What if you don’t have an oven for curing the paint?

On painting lines where no oven is used, the surface treatment throughput can easily be increased by 30-100% with Teknodur Combi 3560. To optimise the throughput, compared to investing in an oven (large investment and high running cost), all that is needed is good air flow and moisture control (low investment and low running cost).

Low VOC emissions

With high solid content ranging between 70-90 vol-%, the 3560 products family also releases very low VOC levels of 60-270 g/L. This is significantly lower than with standard two-component polyurethanes, and the lowest-VOC Teknodur Combi 3560 versions have lower VOC than most water-based two-component polyurethanes.

Not only is it about energy, cost savings and lower VOC emissions, but the 3560 series has excellent long-term durability across a range of industrial sectors.

Check out more stories like this in the latest issue of Protective Coatings Expert