Heavy-duty coating systems for the protection of offshore wind foundations

Heavy-duty coating systems for the protection of offshore wind foundations

Authors: C.Y.LEE, PPG global product support manager for Protective & Marine Coatings (PMC); Kent Holm, PPG global wind power segment manager for PMC; Ronnie Peskens, PPG global product manager for PMC; Eric King, PPG global segment manager, powder & mining, for PMC; and Gerard Geels, PPG senior product specialist for PMC

Introduction

As a result of measures to fight climate change, there is a growing need for energy generation from natural sources like wind and solar radiation. For both energy generation routes, solar and wind, increasing investments are made by governments, energy, and operating companies owning and running these installations.

Currently, many large-sized onshore and offshore wind parks produce significant electricity output. Still, the relative portion of the world’s total electricity consumption (approx. 24.000 terawatt-hours) is low[1].

In 2021, of the total 830 GW of wind capacity installed, 93% were onshore systems, with the remaining 7% offshore wind farms[2]. Onshore wind is a developed technology, present in 115 countries worldwide, while offshore wind is at the early stage of expansion, with capacity present in just 19 countries[3].

Although the installation of large-size onshore wind parks leads to economic electricity production, installing large-size offshore wind parks has gained enhanced interest because of its higher production efficiency. According to a report from the International Energy Agency (IEA)Ref. 1, cumulative offshore wind capacity is forecasted to more than triple by 2026, reaching almost 120 GW. By then, offshore wind additions are expected to account for one-fifth of the global wind market. Global capacity additions of offshore wind are set to reach 21 GW by 2026, thanks to rapid expansion in new markets beyond Europe.

However, the construction and operation of offshore wind parks bring many technological challenges that need to be overcome to reduce the operational and financial risks of these mega investments. The more difficult installation circumstances, together with the harsh environments to which the wind towers are exposed, are the main challenges to deal with. This requires high-quality construction and protection materials to ensure a prolonged lifetime together with minimal maintenance, which is difficult and costly.

This paper is meant to review typical protective anti-corrosion coating technologies used on fixed and floating offshore wind-tower foundations that are qualified by leading performance standards such as Norsok M-501. Ref. 2 At present, typical generic coating technologies qualified for fixed offshore wind foundations are either reinforced epoxy- or glass-flake unsaturated polyester based. Both generic coating types have their specific properties and will be further reviewed.

Chemical nature of heavy-duty protective coatings for wind tower foundations

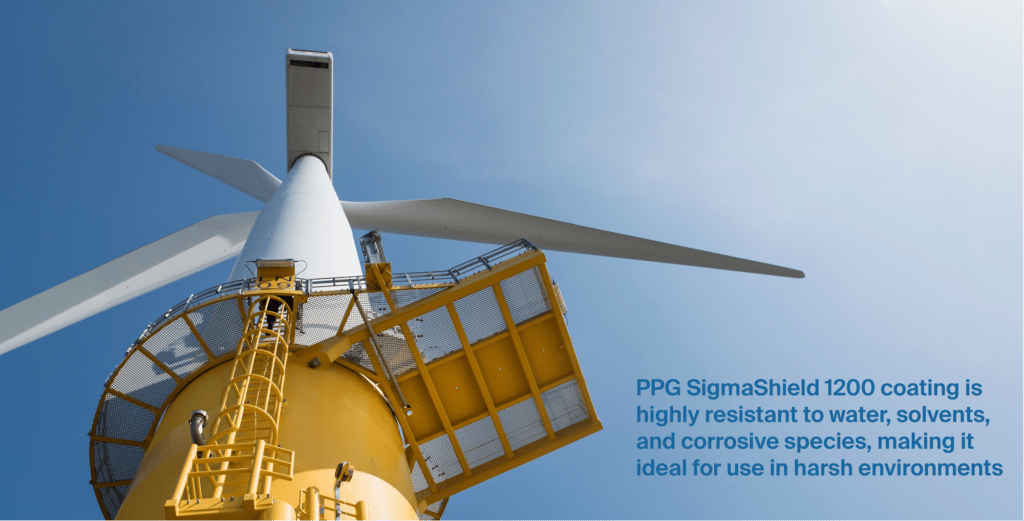

To understand the application and performance properties of the preferred coating categories, deeper insight into the chemistries is needed. Two-pack epoxy coatings, in this case, so-called high build, solvent-free, two-pack epoxy coatings are composed of a mix of a low viscous epoxy resin and an amine curing agent. This leads to a dense water impermeable crosslinked polymer matrix. To further enhance the water impermeability and thus the protective properties of an epoxy coating, so-called novolac phenolic epoxy resins can be used. The resulting coating (e.g., PPG SigmaShield 1200) has a high crosslink density, which gives it superior mechanical properties such as high stiffness and toughness. The cured coating is also highly resistant to water, solvents, and corrosive species, making it ideal for use in harsh environments. Besides the resins used, these coatings are further engineered with mineral or ceramic reinforcement pigments.

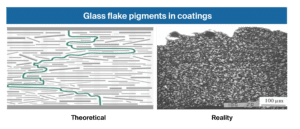

The two-pack unsaturated polyester coating is based upon unsaturated polyester resins and cured by minimal amounts of a peroxide catalyst. Adding these catalysts generates an auto-polymerization reaction whereby the unsaturated polyester polymer partly crosslinks, partly homopolymerizes, and solidifies. To densify and fortify the solidified polyester matrix, typically, large amounts of laminar glass flakes are added. It is claimed that using laminar glass flakes reduces the ingress of water into the coating film providing better corrosion protection of the steel substrate to which it is applied.Ref 3 However, microscopic pictures of glass flake-containing coating films show a rather disorganized random positioning of the glass flakes within the film, and so the added value to the anti-corrosion functioning of the coating can be disputed. High loadings of glass flakes also increase the viscosity of the polyester coating, so considerable amounts of reactive diluents like styrene or vinyl toluene are to be added. These diluents have a strong, pungent smell and make the use of polyester coatings less user-friendly. Recently, styrene-free unsaturated polyester glass flake coatings (styrene-free UPE coatings) have been introduced to reduce the strong smell, making the product more pleasant to use.

This crosslinked resin matrix of high-build epoxy coatings shows, aside from water resistance, also excellent resistance against a variety of chemicals such as alkalis and solvents. Particularly in cases where cathodic protection (CP) systems like galvanic anodes or impressed current are used, the alkali resistance of the polymer matrix is critical. The CP systems will generate an alkaline environment by the electric decomposition of water in case of coating damages or failures.

Aside from the alkalinity that develops when CP systems are activated, stationary sea water inside the wind tower foundation gradually increases in pH. The higher the PH of the seawater, the more it is aggressive to coating systems, mainly when resin systems are susceptible to such an alkaline water environment. Polymerized polyester resin matrices are known to be less tolerant to alkaline exposure environments due to the ester moieties/building blocks within the resin matrix and so are considered less performant to these high pH exposure conditions.

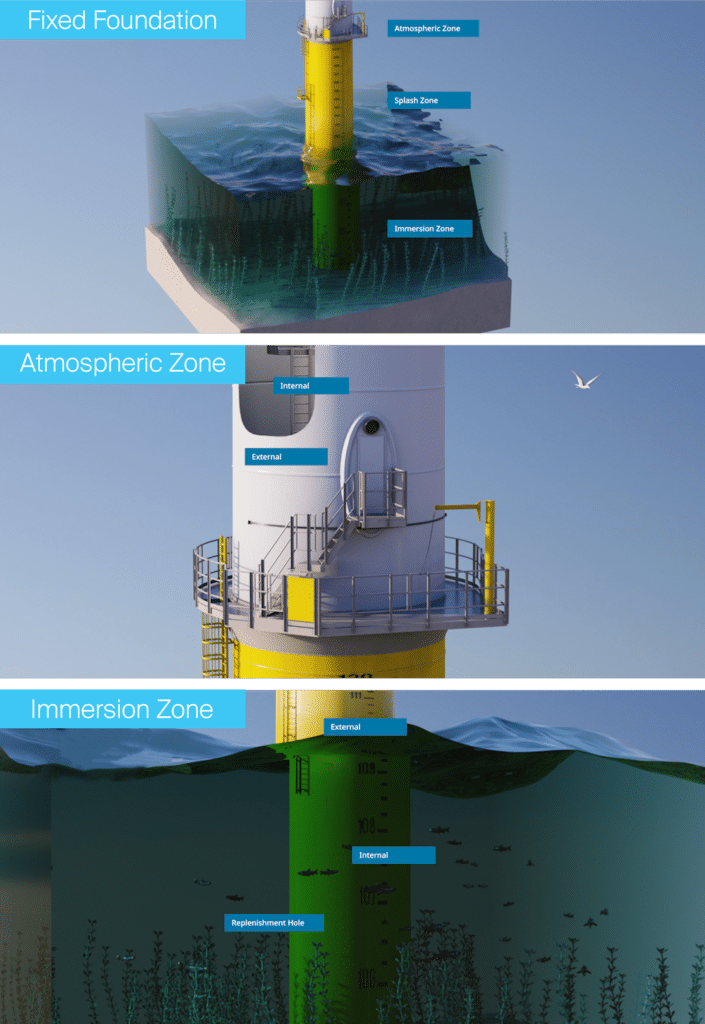

Wind tower foundation coating performances in offshore exposure conditions

The marine environment to which the coating-protected wind tower foundations are exposed is extremely harsh and corrosive. Various exposure zones can be identified: atmospheric saline conditions (transition piece atmospheric zone) are combined with partial variable atmospheric /seawater immersion (transition piece tidal/splash zone) and complete seawater immersion (below L.A.T. seawater zone). Where foundations are embedded in the sea bottom, typically anaerobic non- or minimal corrosive exposure conditions occur, and in most cases, no coating protection is applied. Note1 Cathodic protection systems, either by galvanic anodes (GACP) or Impressed Current (ICCP), are generally installed to protect against potential Microbiological Induced Corrosion (MIC). Ref 4

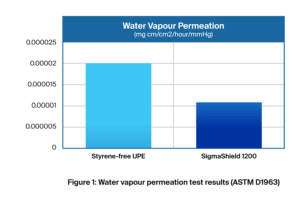

The second least corrosive exposure environment is the full seawater immersion zone; still, protective coating systems should have good seawater resistance in combination with compatibility of installed cathodic protection systems (either galvanic anodes or impressed current systems). Here two-pack epoxy systems generally provide more long-term performance over unsaturated polyester coatings. Water permeability is considerably lower for the reinforced novolac epoxy PPG SigmaShield 1200, limiting the activation of the cathodic protection system.

Moreover, when alkalinity (decomposition of water molecules) is generated due to CP system activation, the ester moieties in the polyester resin matrix are more sensitive to saponification and may break down. This may cause progressive detachment in areas where the coating is damaged or even blistering of the coating system when the water permeability resistance is insufficient. Such

phenomenon can occur, particularly when the film thickness of the coating system is too low.

PPG SigmaShield 1200, a solvent-free reinforced novolac epoxy coating, has an excellent and long track record on underwater parts of cathodic-protected seagoing vessels. This practical experience confirms the reliable performance of the submerged area on wind tower foundations.

Note 1.

The installation of the tower foundation into seabeds is thought to create extensive mechanical damage to the paint system. Practice shows, however, that this mainly occurs at the very bottom end of the foundation and that the majority of this foundation part is effectively protected by an intact paint system. Windfarm owners who still would like to protect the wind tower foundation interface soil/seawater area with heavy-duty coating systems can opt for a zinc-rich primer together with an erosion-resistant coating like PPG SigmaShield 1200. For the inside, to prevent occurrence of Microbiological Induced Corrosion (MIC), an identical paint system as selected for the external can be considered.

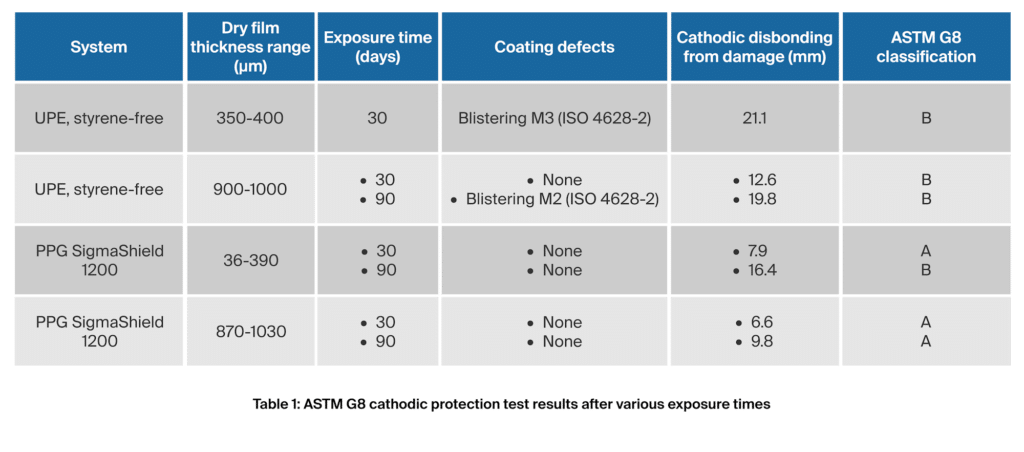

The comparative performance to Cathodic Protection systems of a styrene-free UPE coating and the reinforced novolac epoxy coating PPG SigmaShield 1200 are tested according to ASTM G8. Blasted steel panels coated with various dry film thicknesses are exposed for up to 90 days to artificial seawater and a -1500 mv potential. In the center of the coated panel, a standardized artificial damage is made.

After 30 days and 90 days of exposure time, the progressive cathodic dis-bonding from the artificial damage is measured together with an evaluation of the overall performance of the coating system. The results are presented in Table 1.

The ASTM G8 90-day test results of coated panels with the recommended high dry film thickness reveal that the styrene-free UPE coating has a significantly higher sensitivity to cathodic dis-bonding than PPG SigmaShield 1200. In addition, the styrene-free UPE coating reveals a blister formation, likely the result of saponification of the polyester resin.

At reduced film thickness, the styrene-free UPE coating is even more sensitive to cathodic dis-bonding. Moreover, the coating reveals widespread blister formation. Also, it is likely the result of enhanced saponification of the polyester resin.

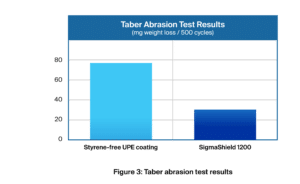

The wind tower foundation soil-seawater area might be exposed to heavy erosion of sea sand and any other debris moving around at the sea bottom surface. It is, therefore, important that the coating shows long-term, superior abrasion resistance. This property is measured by the so-called Taber Abrasion testing following ASTM D4060. Results of a comparative measurement of a styrene-free UPE coating and the reinforced PPG SigmaShield 1200 are illustrated in Figure 3. It shows that a coating composed of a styrene-free UPE resin and glass flakes is significantly less resistant to abrasive forces than the reinforced PPG SigmaShield 1200 novolac epoxy coating.

The splash/tidal zone is definitely the most corrosive area of all at wind tower foundations. At this zone, a mix of seawater exposure and the atmospheric saline environment is present. In addition, variable temperature conditions are present and strongly influenced by the weather conditions where the wind tower foundations are located. Here, coating systems should comply with Norsok M501-System 7A performance criteria. Both the styrene-free UPE coating and PPG SigmaShield 1200 fulfill these Norsok test criteria.

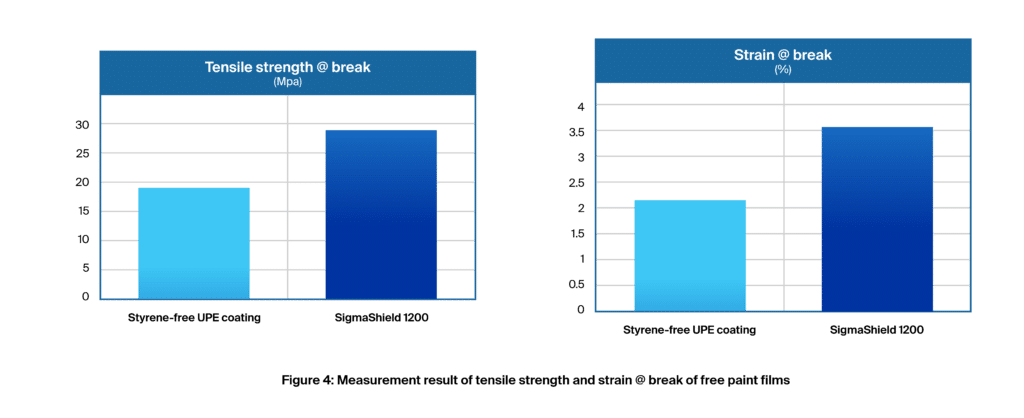

The environmental temperature variations also require that the coating is resilient enough to avoid stress cracking. Any cracks can result in progressive delamination and corrosion. Moreover, the flexural strength of wind turbine towers is a critical engineering consideration because wind turbines are exposed to dynamic loads and environmental conditions that can cause flexural stresses. The tower must be designed to withstand these forces to ensure safety and longevity.

Likewise, the coating system, as applied at the various wind tower areas, should be able to withstand these flexural stresses and should not show any tendency to crack, exposing the steel substrate to saline corrosive conditions.

To understand how the styrene-free UPE coating compares to the novolac epoxy PPG SigmaShield 1200, free paint films of about 1000 microns are measured on their elastic properties (tensile strength and strain at break following ASTM D 638 and D 2370 after a 3-month cure at ambient conditions. These measurements show that PPG SigmaShield 1200 has considerably better elastic properties than the styrene-free UPE coating.

The splash-tidal zone area is also more prone to coating (impact) damages from floating debris, ice, and mooring maintenance vessels. Anti-corrosive coatings formulated with glass flakes are said to be better resistant to impact forces because of the reinforcement properties of the laminar glass particles within the resin matrix. To understand if this makes a styrene-free UPE coating stronger than PPG SigmaShield 1200, reinforced with mineral hard pigments, coated panels with a film thickness of around 500 microns have been subjected to various impact forces from 3 to 10 Joules according to ISO 6272-1 test method. Subsequently, these panels have been exposed to Salt Spray testing (ASTM B117) for 7 days. Tests results demonstrate that the styrene-free UPE coating shows significantly more corrosion formation than the PPG SigmaShield 1200, of which the impacted areas show no corrosion at all.

This clearly indicates that the latter maintains its protective properties, while the corrosion formation at all impacted areas of styrene-free UPE coating shows adhesion loss at the coated steel interface. This illustrates that using glass flake pigments provides no superior impact damage performance over novolac epoxy coatings formulated with alternative reinforcement pigments.

The eventual damage, together with applied CP systems, can also initiate cathodic delamination, to which two-pack epoxy coating PPG Sigmashield 1200 provides more resistance than styrene-free UPE coatings.

The presence of marine fouling like algae, mussels, and barnacles can also affect coating integrity. Particularly, barnacles adhere firmly and may penetrate the coating. Surprisingly, the high gloss and smooth PPG SigmaShield 1200 surface, as practical information from field experience confirms, shows good tolerance against adhering fouling. If this marine fouling is to be removed, high-pressure water cleaning is often sufficient to recover the original coating surface.

Styrene-free UPE coatings have a mat and rather coarse coating surface appearance (use of large-size glass flakes) and are, therefore, more prone to firm adherence to marine fouling species. When these species need to be removed, it requires scraping or even sweep or wet blasting techniques, likely resulting in substantial coating damage and follow-up repairs.

The wind tower atmospheric transition foundation is exposed to atmospheric conditions only but still needs heavy-duty anti-corrosion systems to protect the foundation against the aggressive saline climatological conditions. For the sake of application simplicity, the same coating system can be applied as is used for immersion and splash-zone areas. Although PPG SigmaShield 1200 has an initial high gloss, when exposed for long periods to UV radiation, chalking will occur, thus reducing its gloss and fading in color. Such chalking of the coating surface also occurs for unsaturated polyester coatings, noticeable by discoloration.

Typically, an additional topcoat is applied for aesthetical reasons and to secure optimal UV resistance. Top coats to be applied are either based on Polyurethane or Polysiloxane resin technology. Both are known for their excellent long-term gloss and color retention. These types of topcoats can be used on top of either PPG SigmaShield 1200 or unsaturated polyester coatings.Note2

On-site coating system maintenance

Visual, small damages to the coating systems need to be repaired on a regular basis. Generally, annual inspection routines will identify where these damages have occurred. Where possible, power tooling should be used to remove corrosion and poorly adhering coating. Subsequently, rinsing with tap water is required to remove any salt contamination. This is essential to avoid any osmotic blistering of the coating system at a later stage. It is recommended to use a primer coat suitable to be applied to the power tooled and water-rinsed damaged area (St-2 cleanliness). After primer application and curing, the original coating system can be applied. Between each coat, tap water rinsing should be used to ensure that no soluble salts are embedded.

The above repair procedures on-site at wind tower foundations are quite difficult to execute. User-friendly coating maintenance systems are to be used. Two-pack epoxy coatings and PPG SigmaShield 1200, in combination with the PPG SigmaPrime 200 primer, have such tolerant application properties. Suitable alternative coatings (e.g., PPG SigmaShield 880), fully qualified for offshore wind tower foundation maintenance procedures, can also be used. Unsaturated polyester coatings are less application-friendly for on-site maintenance procedures. Tuning the mixing ratio with the low amounts of peroxide catalyst and the resulting short pot life makes manual application under these difficult application conditions hardly possible. Likely analternative coating repair systems needs to be used.

Note 2

The use of topcoats can also be considered for the splash zone/tidal coating system. It will prevent the chalking of the anti-corrosive coating system, and it may additionally improve the long-term adhesion performance of the coating system. Ref.5 Moreover, the use of UV resistant two pack topcoats at splash zones minimizes migration of chalked coating microplastic particles into the aquatic environment

Lifetime expectations of heavy-duty coatings

As indicated in the previous chapters, the splash/tidal zone is most susceptible to corrosion due to paint system damages or failures. Still, owners and operators would like to rely upon long-term flawless corrosion protection with minimal coating system maintenance operations.

To provide reliable lifetime projections, the frequent successful use in the shipping and oil and gas industry is a good indication of the excellent protection properties of the PPG SigmaShield 1200 coating system. Track records of multiple vessels and oil and gas installations confirm that after 10 years or more in operation, minimum maintenance is required. Even with ice-going vessels, this coating system shows excellent corrosion protection and outstanding impact damage resistance. The suitability of PPG SigmaShield 1200 for wind tower foundation protection is further supported by full compliance with Norsok M501- System 7A performance requirements.

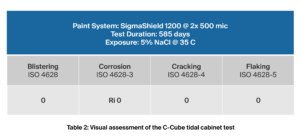

But how can the industryestablish reliable data for longer lifetime expectations, such as 30 years+, as frequently demanded in the offshore wind tower industry? For getting insight into such lifetime expectations, Electro Impedance Spectroscopy (EIS) testing is most suitable. Accelerated testing and focusing on the eventual degradation of the impermeability function can be monitored. When there is little or no change in impermeability after runs of accelerated testing, extrapolation can be made to the real-life performance of the coating system. Such EIS testing of the PPG SigmaShield 1200 system (2x 500 microns) has been performed by the independent test institute C-cube. After 585 days of exposure to 5% NaCl @ 35°C in C-Cube’s tidal cabinet, no signs of any significant coating degradation have been observed (see Table 2).

The EIS measurement data show that the barrier function (BI) after the 585 days of exposure to Salt Fog, Tidal, and Seawater only dropped about 10 % compared to the ideal resistance/insulation behavior. The permeability of the coating system dropped to minimal or none. The absence of a decline in permeability index (PI) confirms that the coating displays no signs of degradation during the extended test period of 585 days.

This allowed C-cube to conclude a lifetime projection of the PPG SigmaShield 1200 coating system:

Quote: “Based on extrapolation of the ISO 12944-9 (CX+IM-4) test duration, the system PPG

SigmaShield 1200 @ 2x 500 micron is expected to have a technical lifetime of 50 years or beyond “Unquote.

EIS measurement data of unsaturated polyester coatings are not publicly available and, therefore, could not be compared in this paper with those of PPG SigmaShield 1200. It is thought, though, that the superior EIS performance of PPG SigmaShield 1200 cannot be matched. The long-term practical experience supported with the EIS performance data indicates that PPG SigmaShield 1200 provides offshore windfarm owners with reliable long-term corrosion protection for many years in service.

The application process of two-coat heavy-duty coating systems on wind tower foundations

Critical for realizing a long-term anti-corrosion system is secure substrate pretreatment in combination with a correct and high-quality application process of the right heavy-duty coating system.

A grit-blasted surface cleanliness of ISO Sa 2.5 with a minimum surface profile of 50-100 microns is required. Soluble salt presence should be avoided and not exceed 20 mg/square meter as specified in Norsok M-501 and in wind farm project specifications. Once these substrate requirements are fulfilled, the paint system will show excellent adhesion performance. Moreover, the minimal presence of soluble salts prevents that under humid or immersed conditions, osmotic processes will not occur that could lead to blistering and coating detachment.

Following grit blasting, coating application will generally take place in indoor conditions. These heavy-duty coatings are applied by single-feed airless (60:1) spray equipment. Here special attention should be given to the pot life of the mixed coating. Solvent-free epoxies, like PPG SigmaShield 1200, have acceptable pot lives of 60 minutes or more. This gives the paint sprayer sufficient time to apply the amount of mixed coating. Another advantage is that PPG SigmaShield 1200 has wide application tolerance in the film thickness range. Dry film thicknesses can be applied up to 750 microns without risks of sagging.

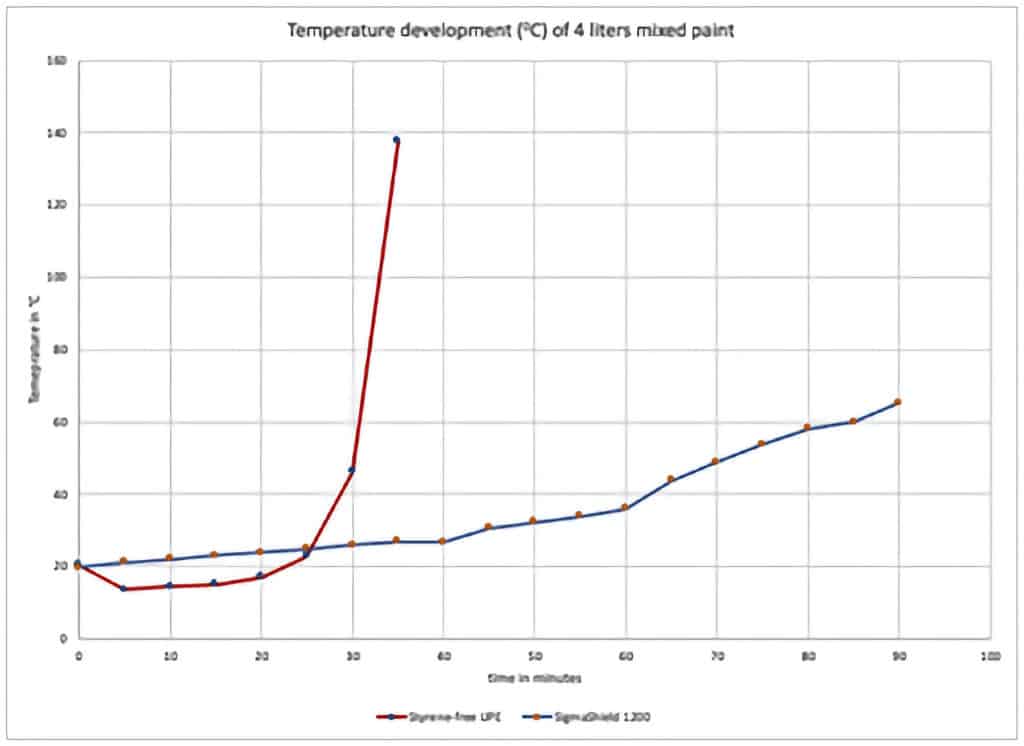

Figure 6.: Temperature development during pot-life

In the case of unsaturated polyester coatings, depending on application temperature, variable amounts of the peroxide catalyst should be added to control the vigorous reaction speed of the mix. In certain application conditions, this should be even combined with a reaction speed retarder to avoid an unworkable application process as the pot life is far too limited to allow the paint sprayer to use the mixed volume. Spraying the paint material too close to the end of the pot life also results in risks in creating a non-homogeneous, coarse coating finish and may require corrective work after curing the coating. All in all, unsaturated polyester coatings need careful tuning of the various mix ratios and highly professional and skilled applicators for realizing a flawless application process.

To avoid pot life issues during the airless spray application, more frequently, twin-feed airless equipment is used. Although the investment cost of this spraying equipment is high, the automatic dosing and mixing of the curing agent just before the spray nozzle overcomes the issue of short pot life, as may occur with single-feed airless equipment. Twin-feed airless equipment also allow the use of large-size packaging and avoids cured, unsprayed paint leftovers. This minimizes considerably small packaging and chemical waste of cured paint.

Two-pack epoxies, given their non-critical mixing ratios, are well suited for such twin-feed airless equipment and, when needed for reason of viscosity, can be applied at increased paint temperatures (hot, twin-feed airless application). Moreover, as both the base and curing agent have different colors, the correct mixing ratio can be visually checked by a uniform intended color of the applied coating system. Unsaturated polyester coatings use, as explained earlier, a very low volume of peroxide curing accelerator. This makes the twin-feed airless application highly susceptible to significant dosage variations in the static mixing device of the twin-feed airless spray equipment. In addition, the big viscosity difference between the unsaturated polyester base and the peroxide further complicates proper mixing. The possible performance issues of these mixing ratio variations are not fully understood. This needs more study to ensure that twin-feed airless applications are a risk-free application technology for realizing the secure technical performance of unsaturated polyester coatings.

As the application process of these massive wind tower foundations generally happens indoors, consideration is to be taken for safe and acceptable work conditions for the paint spray operators. Both two-pack epoxies and polyester coatings require all prescribed protection means to avoid contact and inhalation of the paint materials. However, the presence of large amounts of styrene or vinyl toluene within the unsaturated polyester coatings will generate a considerably strong/intense, and nasty odor. Work processes following the application may be retarded as workers simply cannot withstand the bad smell. If the yard or factory is close to housing areas, air exhaust ventilation may also result in odor complaints by neighbors.

Application equipment is advised to be cleaned with strong, low-flammable solvents, like MethylEthylKetone (MEK). Depending on the particular application location, these types of solvents may not be allowed.

Offshore wind foundation coatings systems are typically specified as two-coat systems. So, easy and fast re-coatability of the cured first coat is essential to minimize hold-ups in the production process of the wind tower foundations. Here another shortcoming of unsaturated polyesters is being reported. For unknown technical reasons, the inter-coat adhesion of the second applied unsaturated polyester coats can be poor. In order to correct the occurrence of the variable inter-coat adhesion, the surface of the first coat needs to be pretreated, for example, by mechanical disk sanding. It is a time-consuming activity and increases the application costs for the realization of a full two-coat system. Two-pack epoxies like PPG SigmaShield 1200 show, when applied under the right indoor conditions, no problems in adherence between two coats and without any additional pretreatment of the first coat.

Finally, care should be taken for leftovers of mixed unsaturated polyester coatings. The vigorous reaction speed may develop very high in-can temperatures that may lead to self-ignition and therefore risks of fire. The coating suppliers typically recommend adding water to the leftover cans to avoid the risk of fire. Clearly, good training and discipline of the application team is required to realize safe coating leftover disposal management.

Material handling and logistics (safety and quality)

In the case of using unsaturated polyester coatings, peroxide catalysts are being used to establish curing of the material. A typical peroxide catalyst used is butanone peroxide. Transportation, storage, and use of peroxides need considerable preventive measures to avoid explosion and/or fire hazards. Peroxides can, in time, decompose, resulting in dangerous break-down products, whereby shocks can result in explosions and/or fire. Transportation of the peroxide needs, therefore, careful attention, and when stored, time-based management of stocks by suppliers and distributors is essential to prevent any incidents. The shelf life of peroxide curing agents is short and generally not longer than 6 months.

Summary and conclusions

Offshore wind tower foundations are exposed to extremely harsh environmental and corrosive conditions. For this reason, high-quality, very durable coating systems are to be used at the time of the new building. Moreover, any on-site maintenance and repair of the coating system is difficult and costly.

F1HEND Crew member on deck of boat on offshore wind farm

PPG Protective and Marine Coatings business is meeting the challenge of the wind power industry by providing durable coatings that protect and extend the operational life of onshore and offshore wind turbine installations, including towers and foundations, turbine components blades and other equipment. Learn more here or click here to view our 3D wind power coating selector.

References

- International Energy Agency, Renewables 2021 (revised version December 2021).

Analysis and forecast to 2026 - NORSOK M-501. Surface preparation and protective coating, edition 7.

- Charles J. Watkinson, Graham Greenwood Sole, Flake glass coatings toward the next century, Modern Paint and Coating, October 1998, 30-45.

- DNV-GL, DNVGL-RP-0416 Recommended practice Corrosion protection of wind turbines, Edition 2016.

- Nevena Marinova, Aiala Urbegain, Pablo Benguria, Andreu Travé, and Raúl Caracena, Evaluation of Anticorrosion Coatings for Offshore Wind Turbine Monopiles for an Optimized and Time-Efficient Coating Application, Coatings 2022, 12, 384

[1] https://www.iea.org/reports/renewables-2021