New HVAF development from Castolin Eutectic

Castolin Eutectic, a leading innovator in the protective coatings industry, has launched XupersoniClad, a new thermal spraying service that leverages supersonic spraying technology. This new development promises significant advantages in the protection of components, vessels, and structures from abrasion, erosion, and wear, offering a unique service in the European market.

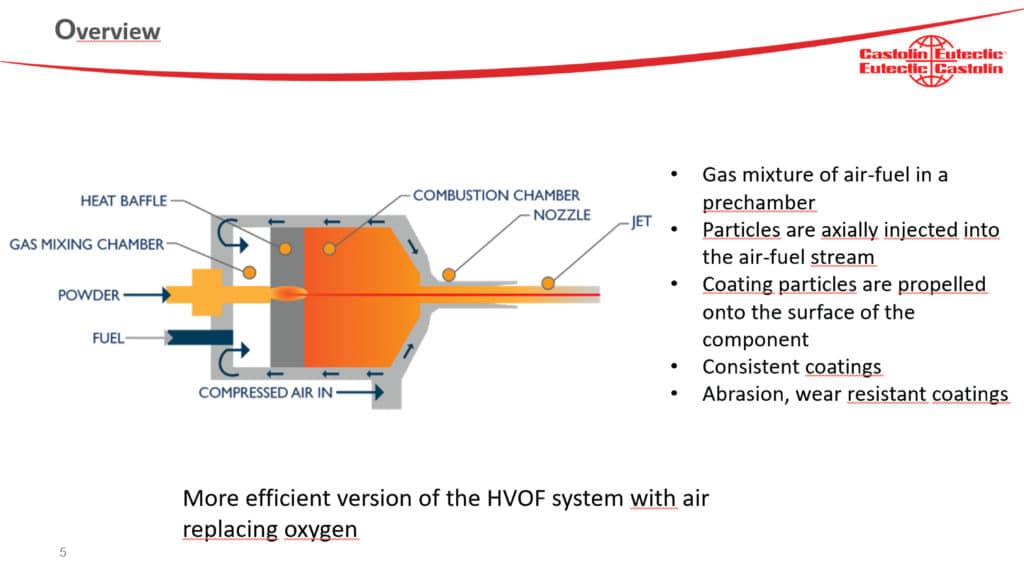

Developed from the high-velocity air-fuel (HVAF) process, XupersoniClad applies abrasion-resistant wear coatings in forms like metal, carbide, and metal alloy powders. It also provides an effective solution for new-generation high entropy alloy (HEA) coatings, combining five or more elements to outperform traditional materials in both room and high-temperature scenarios.

XupersoniClad comes as a breakthrough for industries requiring enhanced abrasion, wear, and erosion resistance, notably recycling, concrete, brick, and tile production industries, as well as vessel and boiler interiors. One significant new application is in mitigating the damaging effects of cavitation on liquid pumps, propellers, impellers, and control valves.

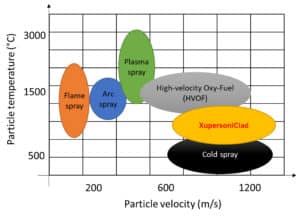

XupersoniClad is a warm spray process, more efficient than the previous high-velocity oxy-fuel (HVOF) process, operating at lower temperatures and higher particle velocity, making it suitable for almost all common thermal spray materials, except ceramics.

The advantages of XupersoniClad are numerous, from a range of coating thicknesses with minimal heat input into the substrate, low deformation, and a smooth, ductile finish, to the creation of a dense, consistent microstructure ideal for corrosion resistance. This process also offers the capacity to apply thin, precisely layered coatings while maintaining high bond strength and resistance to stress-induced delamination.

With the ability to apply coatings to the internal diameter of pipes down to 80mm, XupersoniClad expands its usability even further. An additional feature that accelerates the process is the capability for ‘hot grit’ blasting, which is faster, more focused, and energy-efficient than traditional surface preparation methods.

To deliver XupersoniClad’s benefits widely, Castolin Eutectic has upgraded its facility in Belgium with a mobile container for on-site services, ensuring accuracy and repeatability with the help of a cobot (collaborative robot) to manage large projects.

XupersoniClad comparison with other technologies

XupersoniClad allows the application of various coatings, such as nickel alloys, carbide coatings, and low melting point metal spraying, across numerous industries. These include chemical, waste-to-energy, and biomass plants, and sectors requiring increased resistance to surface abrasion, corrosion protection, and friction coefficient improvement.

This innovative approach also extends to protection against cavitation, offering a well-bonded, dense, and ductile protective coating that can withstand the shock waves that typically damage traditional hard coatings.

Case studies with concrete moulds, cooler plates in cement factories, cyclones, and steel industry fume ducts have showcased XupersoniClad’s potential to revolutionise protection in these key areas.